A New World of High Resolution Cameras

We see footage from convenience store security cameras … usually in a police report or plea for citizen help … and the videos are colorless, grainy and lack detail to see the action clearly. It’s hard to imagine how this could be useful for process study and improvement. On the other hand, we’ve also seen elaborate camera setups to study process problems and operations … but who has time to wrangle that on a regular basis?

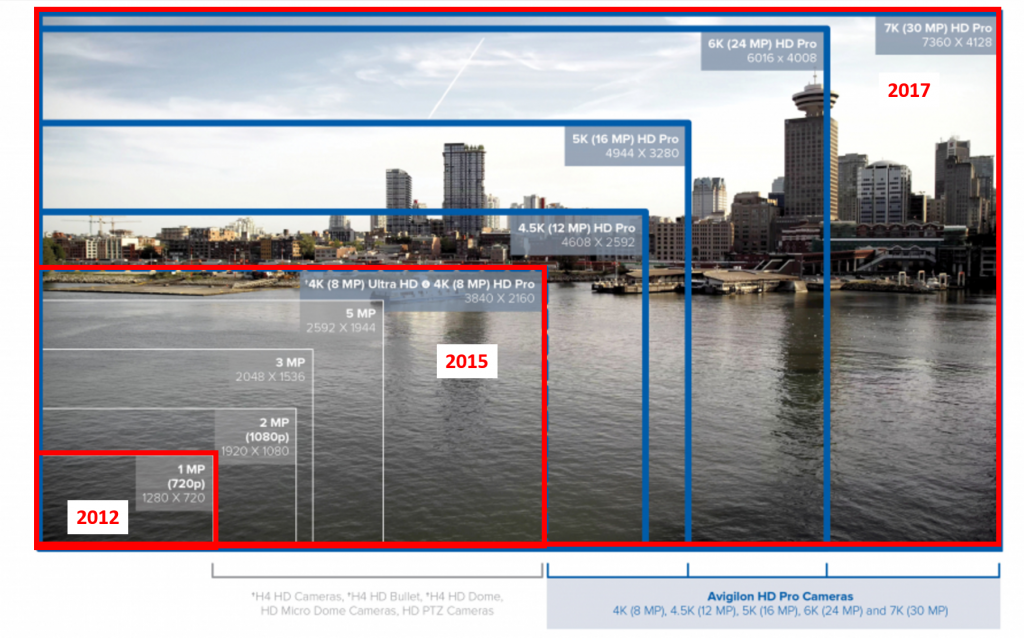

Neither of these technologies compares to the new generation of surveillance camera systems that have emerged in the past 5 years. The following photo (from the Avigilon website) shows the amazing camera improvement that has occurred (the red outlines and dates are mine).

Every major security system vendor now offers cameras at least at the 4K level. Some companies like Avigilon are selling much higher resolution. Their 7K surveillance camera captures an image more than 7,000 pixels wide!

Is this amazing technology really useful? The security industry thinks so, but they still seem hesitant whether super high resolution cameras are more than a niche play. For one thing, a 7K camera emits a massive data stream. If you want to record for any length of time. the networking and storage investment is substantial. Eventually bandwidth and storage will catch up and camera costs will fall, so these cameras are quickly becoming more affordable.

The real question is what can we do with all of this extra clarity and resolution.

I am increasingly convinced that the value proposition for these higher resolutions will be strongest for systems that watch and analyze production operations. There, the extra detail can reveal new management insights about production flow, yields, losses and other big dollar issues. The remainder of this article explain why I think this might be true.

Resolution Extends our Vision

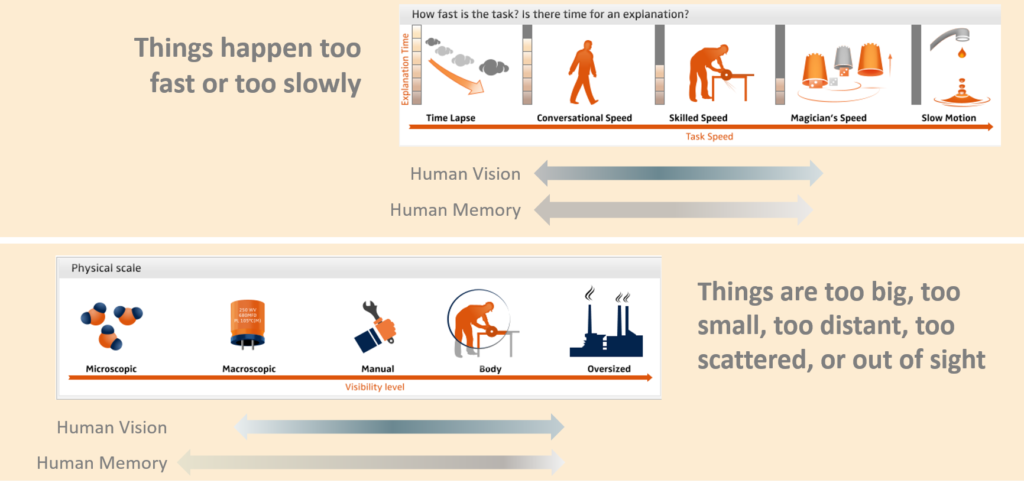

There are many events in a typical factory, warehouse or industrial facility that are a single human has a hard time seeing. This diagram illustrates the range of physical scales that we typically encounter in daily activity. It goes from objects too small for the eye to resolve to vistas that are so big the human eye cannot comprehend them. Humans focus on things in the middle of the eye’s vision. These are the activities that our eyes and brains are designed to view.

This limits our ability to comprehend and manage complex processes, Many of the standard tools in the lean manufacturing arsenal were invented to overcome this limitation. That’s why we value Andon (visual) signals on our production lines. We do bottleneck analysis because we lack the ability or patience to track backups as they repeatedly grow.

Wider, Clearer Vision

It’s human nature to think that we see everything in front of us, but the human eye has a characteristic called foveal vision. Our eye can only focus on a small part of the panorama in front of us. The rest is peripheral vision. The diagram below on the left is a rough approximation of our capabilities … they vary between individuals. In the photo on the right, the red circle shows the part that that seems fully distinct when I look at the lemon tree.

Consider what this means to workers, supervisors, technicians, engineers and managers when they watch activity on a factory floor or in a distribution center. Even if they are watching continuously, they can really only register a tiny portion of what is in front of them. Now consider a video camera. It records every pixel over the entire image with equal fidelity and it can retain that fidelity as long as you record the video stream. You can return at any time and view the image and every part of the scene at identical levels of detail.

Now consider what is becoming possible with the new, high resolution cameras. The following examples come from the Avigilon (www.avigilon.com) web site. You have to open the linked page and look for the demonstration image (like the one shown on the left) a bit down the page. Since no web browser or monitor can do justice to a 4K … let alone a 7K … image, you must hover the cursor over the image to see a small window with the full camera resolution. Move the cursor and see how much more detail you can discern. A high resolution camera can record that level of detail across its entire image and every image can be saved for viewing at some arbitrary later date.

A High Resolution Overview of Operations

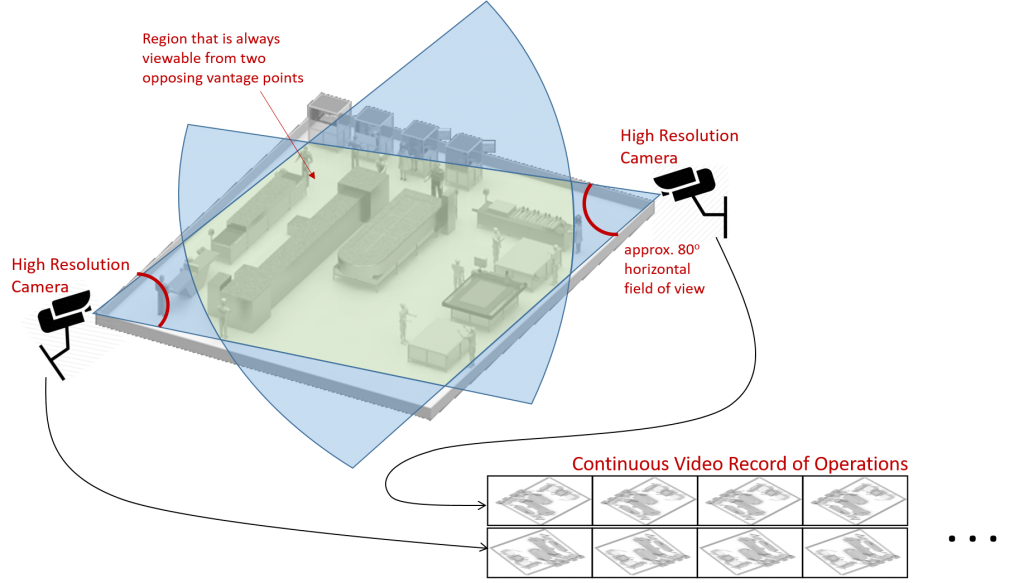

My concept is to use this capability to make a complete recording of all facility operations. To do that, mount several high definition cameras around the periphery of the work area … two at a minimum. As the following diagram shows, the cameras should view the space from opposing vantage points. The key is to overlap the fields of view. A given activity might be hidden from one camera, but the chances of it being hidden from all of the cameras is much less. Add another camera or two to improve the coverage and see better into potential blind spots.

A simple system like this promises several intriguing possibilities:

- The system can record a complete history of activity in the facility … perhaps not every detail (an object might block the view), but certainly all major actions and occurrences. It may not tell you why or how something happened, but it will probably establish what happened, when it happened and what was going on nearby at time of occurrence. In other words, it can give a powerful visual context to everything that has recently happened in the facility.

- The system should be able to see and record the movement (flow) of all people, equipment, and product in the facility. Understanding process flow is often the most difficult thing that process managers have to do. I am especially intrigued with the potential of analysis tools like Dartfish to mark, track and analyze movements and flows. How might this help when you are trying to improve spread-out activities like shift changes?

- The system will generate a wealth of material for training and remote problem solving. If there are “interesting” events that you would to prepare your staff to handle, chances are they will have appeared somewhere in the video record. Find them, export the video (possibly from several angles), and show it to your employees during training. Give them videos of real situations to discuss and understand.

- The extensive, high quality video record of operations can be made more useful and searchable by adding meta-tags … either automatically from the security technology or after-the-fact with post-processing in analysis tools like Dartfish.

Thanks to ruthless competition in the security industry, systems like this are falling rapidly in price … especially compared to the potential gains in flow efficiency, reduction in loss and improved staff skills. You can buy a high quality 4K IP camera (indoor use) for $400 to $800. This is where I suspect that high resolution (4K at least, and perhaps 7K) video may find a large and lucrative new application.

Of course, if you want to apply video in continuous improvement, the high level overview is important, but far from enough. You will want to deploy other cameras of various types to watch more localized points of interest. Nonetheless, the output from those cameras will be greatly enhanced if it can be viewed in the full overall context that this type of system would provide.