Typical manufacturing and business operations involve a huge range of independent activities. One of the key differences between the various activities is the way in which they unfold over time … their speed and timing. Sad to say, our traditional operations management tools do a poor job of analyzing and managing these aspects of work. Yet, when we try to develop new processes (especially ones that are accelerated by automation), perfect their operation and teach them to workers, we can’t escape the effect of speed or timing.

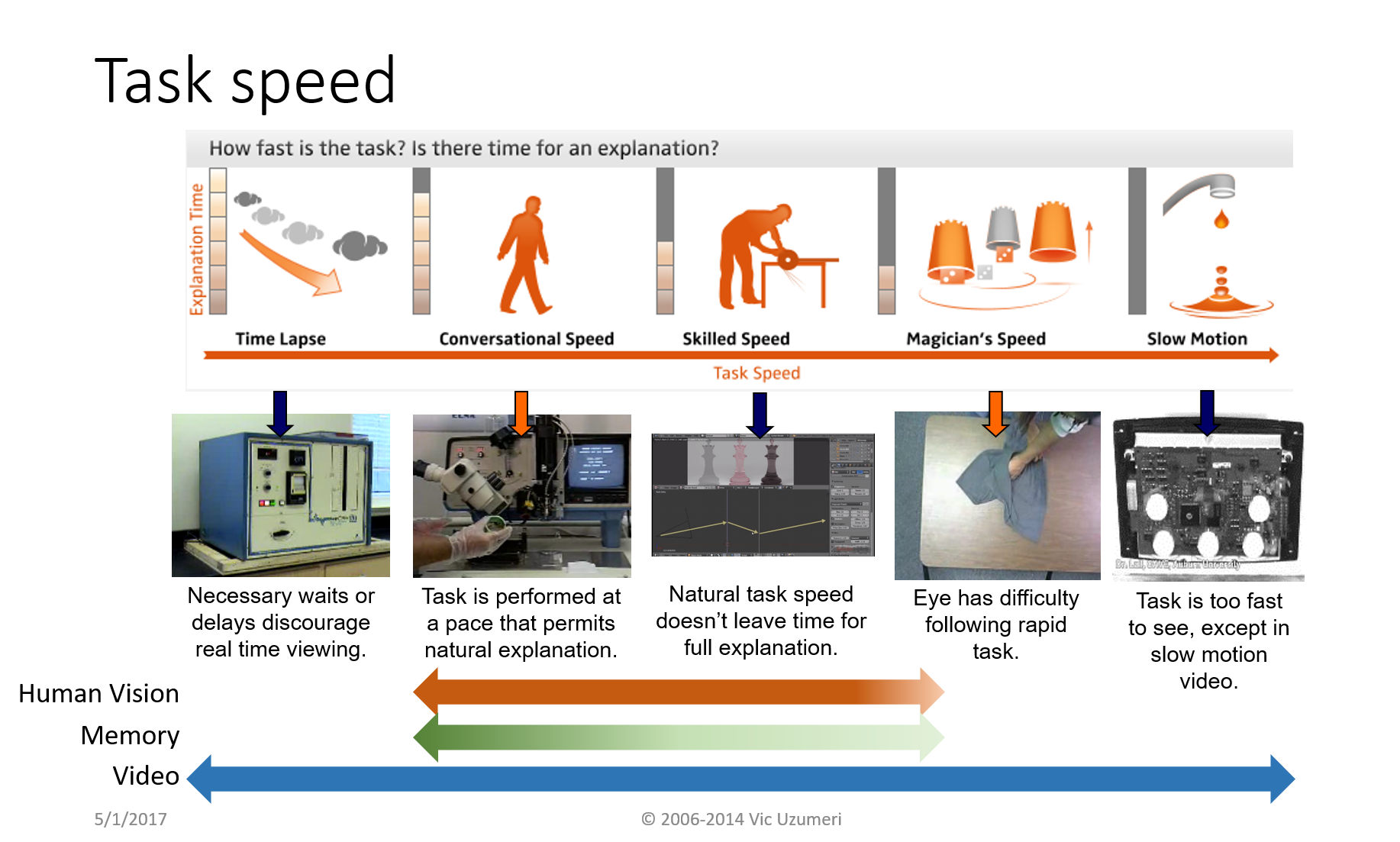

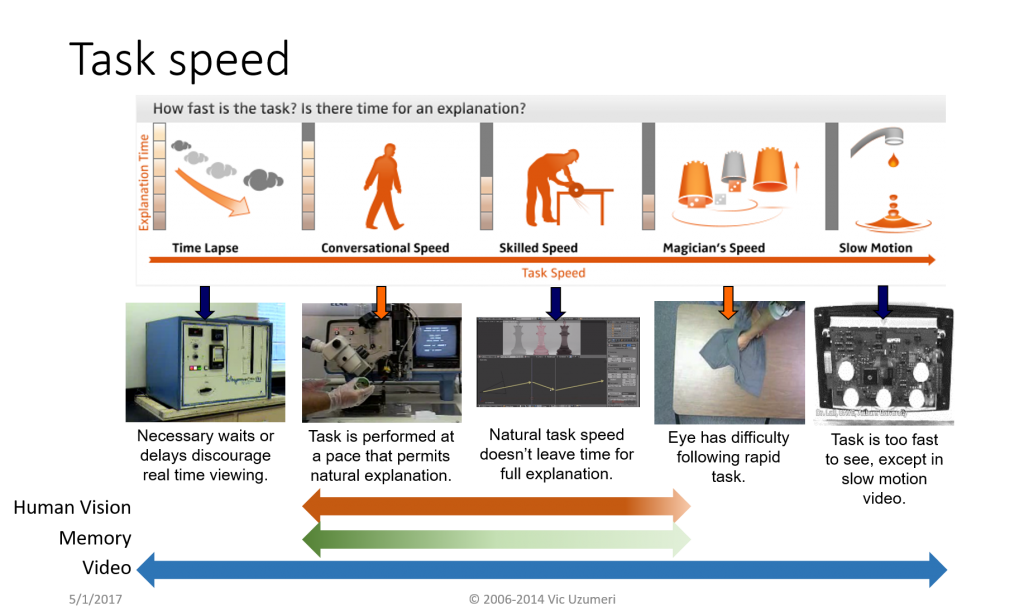

We can, however, do much better if we use video more creatively and aggressively! For this post, I am going to focus on speed. Timing is arguably just as important, but I will examine it in a future post. The following diagram illustrates how tasks can occur at widely varying speeds.

Some tasks take a long time to unfold. Think of things like concrete curing or bread baking. As much as we wish, we can’t make them go much faster … and they are hard to watch. Even if key aspects are visible to the eye, the processes effectively lie outside our view. No one wants to stand around and watch one item for hours or days.

There are a lot of tasks that occur at speeds a human can follow. They are fast enough to finish within a reasonable viewing time, but slow enough that the human eye and brain can follow. Even there, faster tasks can happen faster than we can fully understand. We can see them happen, but it is hard to process and analyze how or why they are happening. At the extreme ends, experts often do tasks faster than other mere mortals can follow. What was that? How did you do that? To the expert it is all perfectly clear. To the observer it can approach magic.

Finally, there are tasks and operations that happen (sometimes much) faster than the eye can follow. We can describe how they work, but we cannot see them. These types of processes are hard to debug and even harder to explain. Explain what happens to the soccer ball when it is struck by the foot.

In addition to the visibility and patience issues, there is a concern with memory. Really slow activities are actually the easiest, since we can rely on note-taking. Anything faster than that and it becomes a chore or impossible to record everything that happened … unless the recording medium is video.

One of the most exciting characteristics of an operational surveillance system is the fact that recent camera and recording advances make it very easy to study activities over the full range of these speeds. For tasks that unfold slowly, a camera is patient and attentive … a video surveillance camera even more so. It will collect continuous video footage for hours, days or even weeks. We don’t have to set it up … it is always on by default. For faster tasks, video can capture discrete images at multiple frames per second … and typical recording speeds are rising quickly.

The following video shows how a commercial camera can slow action down in a useful way. Watch this waffle-baking machine eject waffles from the grill with an air jet. The action is shown at speeds ranging from normal, real-life speed down to approximately 1/15 speed or about 1 frame per second. As the speed drops, watch how details emerge. You can see waffles come off earlier in certain areas or watch as they twist and turn as they fall. By the way, nothing in this video is abnormal or indicative of a production problem. These are Belgian waffles that are dropped on the waffle iron unconstrained by side walls (as with an “Eggo”). A certain amount of natural variability is inevitable and desirable.

Unfortunately, some of the native resolution is lost by being published for web viewing. To get the full detail in both speed and resolution, you need to view it with suitable software on a good monitor driven by a laptop or desktop PC. For that, there are many possible software choices. The examples above were engineered in Adobe Premiere Pro CC to control the different speeds and add the titles. Premiere Pro has a very cool feature called “time remapping”.

However, I suspect that a quality manager or industrial engineer probably doesn’t want to learn Premiere Pro or fiddle with its controls. They need a tool where they can quickly examine behavior, play it back and forth and stop on frames to try to figure out what is going on. That is well-supported in Dartfish software (www.dartfish.com), on the desktop or in their mobile apps.

A ticket to the world of slow motion (and time lapse) is now a free bonus with any credible video surveillance system. Combine the standard surveillance technology with best-of-breed video performance analysis system like Dartfish and any operations manager, quality engineer, industrial engineer, ergonomics expert, or machine technician can debug production activity that was previously unseen. Of course, some machines will operate at speeds beyond the reach of these cameras, but many more will give up useful secrets. If the activity involves human actions, you can pretty much guarantee that you will see everything that is going on. Consider some scenarios:

- A highly skilled assembly worker seems to work faster and with less effort than anyone else? What are they doing that is different? If you ask them to demonstrate their actions are hesitant or artificial. Now just “go back to the tape” and watch them until you figure it out.

- A mistake clearly happened, but it occurred so quickly that no one really saw it clearly. “Go back to the tape” and watch it as it really happened. Then slow it down to understand every detail.

- Parts are jammed up as they flow into a machine. By the time you notice, it’s a big pileup and the flow behavior is lost. Extract video from just before the problem surfaced and watch it in slow motion to see how the backup was caused.

These are the types of situations where video can reveal what is really going on. You can always bring a camera (even a phone camera) to the process and record spot videos. But how much easier and more reassuring would it be to know that the video has already been made and is just waiting for you to extract and study it?

What would Deming, Shingo, Imai and the like have thought if they could have had this capability?